The fundamental bending design and style guidelines that a designer requires to consider when modelling a sheet metal part contain wall thickness, bend radii, and bend allowance.

It utilizes an SFA series of oil filling valves, that happen to be designed inside a flange construction and right mounted within the hydraulic cylinder, linked to the tank by using a suction pipe.

Throughout press braking operations, the operator manually positions and manipulates the sheet metal, necessitating shut proximity on the active press brake. This proximity provides significant basic safety problems that must be resolved to adjust to stringent industrial security laws.

Enjoyable information from RapidDirect! We’ve rolled out two exciting updates to enhance your production journey.

When you position the bends too close to each other in style and design, it can cause alignment problems and boost the residual anxiety. Hence, an proper distance among them is important, at the least 3 times of thickness.

Brass can be a malleable and conductive substance, simpler to bend than steel. Numerous grades, like CZ129/CW611N, are commonly useful for forming sheet metal. Brass is commonly most well-liked in electrical, thermal, and plumbing apps as a consequence of its relieve of forming and great conductivity.

The flat sheet is pressed by an higher tool right into a V-shaped lower tool (die) and reshaped in a straight line. The backgauges ensure that the workpiece is positioned precisely.

“Press” originates from the word “presse,” which was applied as being a noun that means “to crush or to crowd”; the expression progressed to mean a machine or tool that applies drive by squeezing.

TruBend Mobile 5000 Have you been searching for effective and versatile automation created to tackle an array of sections and make sure continually superior element top quality? Then the TruBend Mobile 5000 is the ideal solution to suit your needs.

Advanced press brakes could also combine capabilities like automated tool changers, robotic materials dealing with systems, and actual-time bend angle measurement for enhanced efficiency and excellent Management.

With DirectIndustry you'll be able to: Locate the products, subcontractor or company service provider you need

While press brakes share some operational ideas with stamping presses, They can be precisely engineered for bending operations. This specialization allows for higher Management around the bending process, vital for obtaining restricted tolerances and complicated geometries in sheet metal more info parts.

Advanced digital goniometers generally function LCD shows for easy looking at and can be integrated with press brake Regulate systems for automated angle verification and adjustment.

Appropriate assortment and common calibration of press brake gauges are very important for protecting manufacturing high-quality criteria and making certain dependable portion production in sheet metal fabrication processes.

Tia Carrere Then & Now!

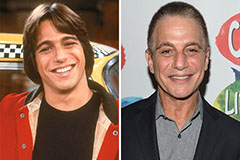

Tia Carrere Then & Now! Tony Danza Then & Now!

Tony Danza Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Judd Nelson Then & Now!

Judd Nelson Then & Now! Elisabeth Shue Then & Now!

Elisabeth Shue Then & Now!